Xinda Motor will briefly talk about the difference between a semi-floating bridge and a full-floating bridge. We know that independent suspension can be divided into double wishbone independent suspension (double AB), McPherson independent suspension, and multi-year rod independent suspension, but the overall bridge can also be divided into full-floating bridge and semi-floating bridge. The floating here does not mean floating, but refers to the bending load borne by the bridge body. Since the bridge body is supported by wheels at both ends, the bending force is mainly generated by two aspects. One is the bending load imposed on the bridge body by the weight of the vehicle body, and the other is the impact force generated by the vehicle bouncing on the ground on the wheels. These two bending loads are different in the force position of the suspended bridge and the semi-floating bridge. In fact, it has been explained in the literal sense that the full floating bridge is that the bridge body bears all the bending force, and the semi-floating bridge body only bears part of the bending force. Where does the other bending force go? Which one is better? Let’s first briefly understand their structure.

The tires, wheels, and brake discs of a semi-floating bridge are installed on the half-axles. You can think of them as an integral part. If you want to remove the half-axles, you must remove the tires and wheels at the same time. If the half-axles are removed, the body of the car cannot be moved and supported. After the half-axles are installed in the bridge body, the wheels are first connected to the half-axles, and then the half-axles inside the body are supported by a bearing. Most of the stress points on the outside of the bridge shell are concentrated on the half-axles. In other words, in addition to transmitting torque, the half-axles of the semi-floating bridge also take into account the body load-bearing, and also need to withstand the bending moment generated by the longitudinal and lateral forces from the outside. It can be said that it is vertical. The advantage of a semi-floating bridge is that it is light and simple in structure, but since most of the stress points of a semi-floating bridge are concentrated on the half-axles, the requirements for the strength of the half-axles are relatively high.

At present, most of the hardcore off-road vehicles on the market, such as Tank 300 Wrangler, Prado Land Cruiser 500 DMAX, and even Mercedes-Benz G-Class all use semi-floating axles. From a structural point of view, friends who often go off-road are not suitable for using wheels with larger negative values. The larger the negative value, the longer the lever arm, which will also increase the load on the half-axle, which is equivalent to reducing the strength of the half-axle in disguise.

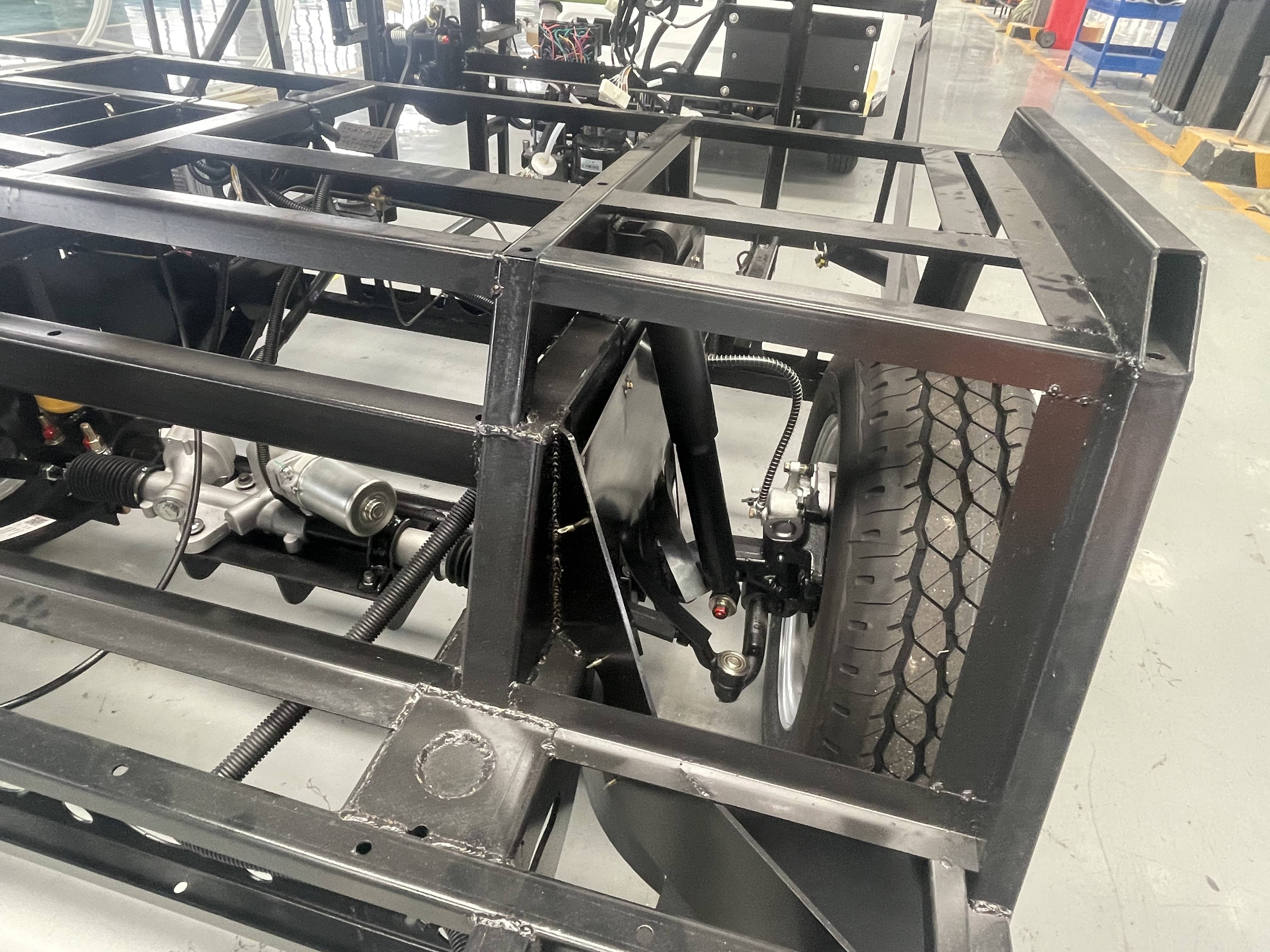

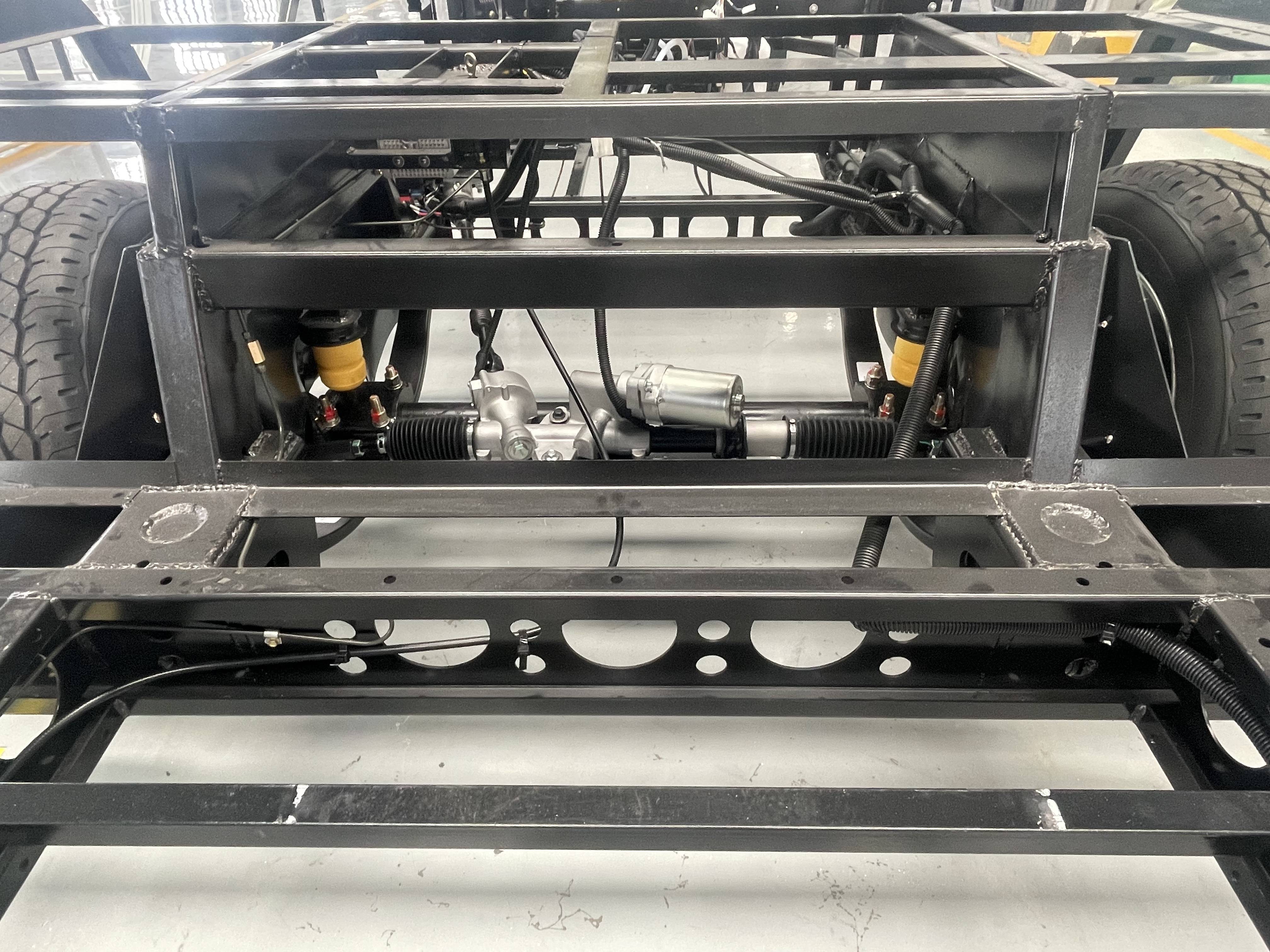

Let’s look at the structure of the full floating bridge. The tire hub of the full floating bridge is installed on the axle head bearing, and the axle head bearing is directly mounted on the bridge tube. It is connected to the bridge tube through two bearings. It can be simply understood that these two parts are a whole, and its half-axle can be removed separately. If the half-axle is removed, the wheel can still support the body, that is to say, it only plays the role of transmitting torque, and the weight of the body and the impact force of the ground are basically borne by the bridge body. Therefore, when the full-floating half-axle and the semi-floating half-axle have the same strength, the full-floating half-axle is not so easy to break and deform. Therefore, the structure of the full floating bridge will be more complicated than that of the semi-floating bridge, and it will also be relatively heavier. It is usually used in trucks or load-bearing vehicles. In hard-core off-road vehicles, the old 7 series all use the full floating bridge structure, which is rarely seen in the new car series. However, BAIC’s BJ40 still insists on using the full floating bridge as the rear axle structure, which is indeed rare.

Post time: Aug-23-2024